본문

Seafarers Management

With Trust & Passion, Your Best Partner.

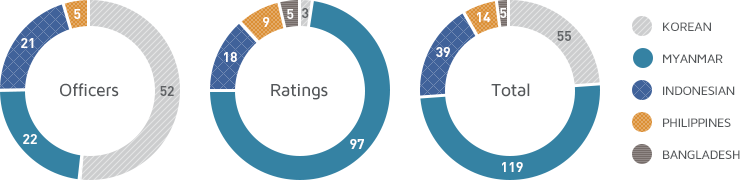

Composition of Crew Employee

| CATEGORY | KOREAN | OVERSEAS | TOTAL | |||

|---|---|---|---|---|---|---|

| MYANMAR | INDONESIAN | PHILIPPINES | BANGLADESH | |||

| OFFICERS | 68 | 24 | 26 | 9 | 0 | 127 |

| RATINGS | 6 | 101 | 23 | 12 | 10 | 152 |

| TOTAL | 74 | 125 | 49 | 21 | 10 | 279 |

Crew Training

- STEP1 Mandatory

- STCW

- STEP2 Upgrading

- PMS

- BRTM

- SHS

- ISM/ISPS

- AOT/ACT

- STEP3 On board(OTJ)

- Anti-collision

- Anti-pollution

- Energy saving

- Garbage control

- LSA / FFA

- Detectors

- Nav / Eng skill

- STEP4 In house(IHT)

- CDI / Major

- Risk assessment

- ISM / ISPS

- ISO

- MLC

- COMPANY PROCEDURE

Safety Control

SHQE Policy of Company

EASTERN TANKER CO., LTD. shall provide the supreme service to the customer, secure safety of the ship and human life and do their best to preserve the environment by establishing and enforcing the SHQE Management System of the company in order to grow as the International ship management company through customer impression by best service and providing the pride to the Shore-based and Shipboard Personnel.

- 1 All activities of the company shall observe the ISM Code, ISO9001, ISO14001, OHSAS 18001, ISM code and International statute and regulations.

- 2 Placing the highest priority on the health and safety of all personnel of the company by providing the work environment safety and comfortable.

- 3 Company shall grasp customer requirements and provide the service where the customers satisfy.

- 4 Company shall prevent hazard factor and accident occurrence possibility.

- 5 Company shall minimize the discharge of environmental pollution materials and remove the cause of resource waste by using the effective resource and energy preservation ways as can as possible.

- 6 Company shall execute surely the measure for drugs and alcohol according to the company procedure.

- 7 Company provides blood test for carcinogenic cargo to all crew in accordance with treatment and medical support procedure of company.

- 8 Company shall make continuous improvement for the efficiency of SHQE Management System.

- 9 Company shall provide appropriate resource and means to appropriate execution and continuous improvement of above SHQE policy. Concrete execution plan shall be reflected in yearly business plan and execute and manage it.

- 10 All staff shall observe the policy, objective and duty performance methods which required by SHQE management system and shall perform faithfully their responsibility and duty.

- 11 President shall entrust MR (Management Representative) / DP (Designated Person) with responsibility and authority which necessary to SHQE management system operation and check the system is properly executed and maintained right way.

Safety Control Structure

- Main manual

- Process control plan

- Procedure

- Guide (Instruction, Information & Poster)

- SHQE Records

Safety management

- 1) Review of SHQE SYSTEM

- 2) Ship's operation (weather information)

- 3) Control of non-conformities

- 4) Control of ISM/ISPS/ISO Audit

- 5) Control of major/CDI inspection

- 6) Supervision of Emergency Response training

- 7) In-house training

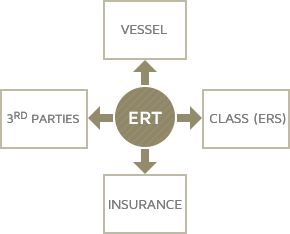

Emergency Response

- STEP 1Open Emergency Response Tram (In ERR)

- STEP 2handling accident, investugation of accident

- STEP 3Analysis of Accident (RCA), Establish Corrective Actions

- STEP 4Launch corrective actions

- STEP 5monitoring and Analyzing corrective Actions and preventive Action

Emergency Structure

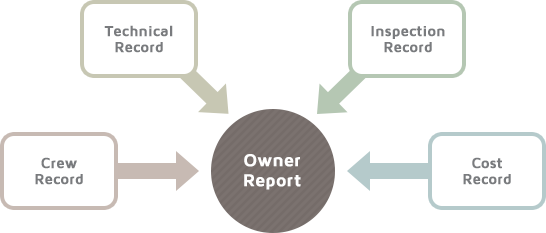

Ship Management & Public Service System

- 1 Oil Management System

- 2 Articles for Ship/Spare Parts and Supply History Management

- 3 Repairing/Servicing Record Management

- 4 Operational Repairing/Dock Repairing Item Management

- 5 Ship Schedule Management

- 6 Budget/Performance Management by Ship

- 7 Ship Inspection Schedule & Item Management

- 8 PMS Management

- 9 PSC Inspection History Management

SHIPOWNER REPORTING SYSTEM

SIRE VETTING / CDI INSPECTION

MAJOR CERTIFICATION

2011 Y ~ (100% PASS RATE)

CERTIFICATION MAINTENANCE SHELL,

BP, PETRONAS, BHPB, TESORO, NESTE OIL, PHILLIPS 66, IDEMITSU

VETTING SYSTEM

- Owner Reputation

- CDI Reports

- Owner Audits

- Terminal Feedbacks

- Ship Inspections

- Casualty Data

- Sire Reports

- PSC Inspection

- ETC

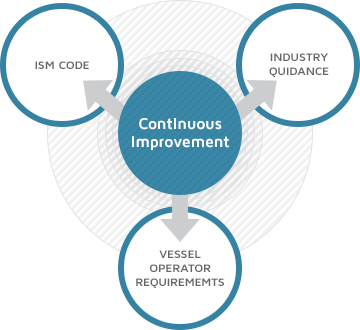

TMSA

Composition of TMSA

- ISM CODE - Safe navigation of the vessel

- INDUSTRY GUILDANCE

- ISO 9000 (Quality Management)

- ISO 14000 (Environment Management)

- ISO 18000 (Health Management)

- Vessel Operation Requiement

- Personnel Management, Organization Management

- Risk Evaluation Training, RCA Training etc

- Management of Change

- Composed of change management and 12 elements

including total numbers questions are 254.

(Each element has 1~4 stage and each stage has 3~6 questions.)